Garage Floor Tiles vs Epoxy: Which Option is Right for You?

A garage floor tile surface is a modular flooring option made from materials such as PVC, rubber, or rigid polypropylene. It provides durability and straightforward installation.

Epoxy flooring is a coating applied directly to concrete. It is composed of a resin and hardener that chemically bond to form a thick, durable surface. This coating provides a seamless, glossy finish that resists spills, abrasions, and wear, making it ideal for high-traffic garage areas.

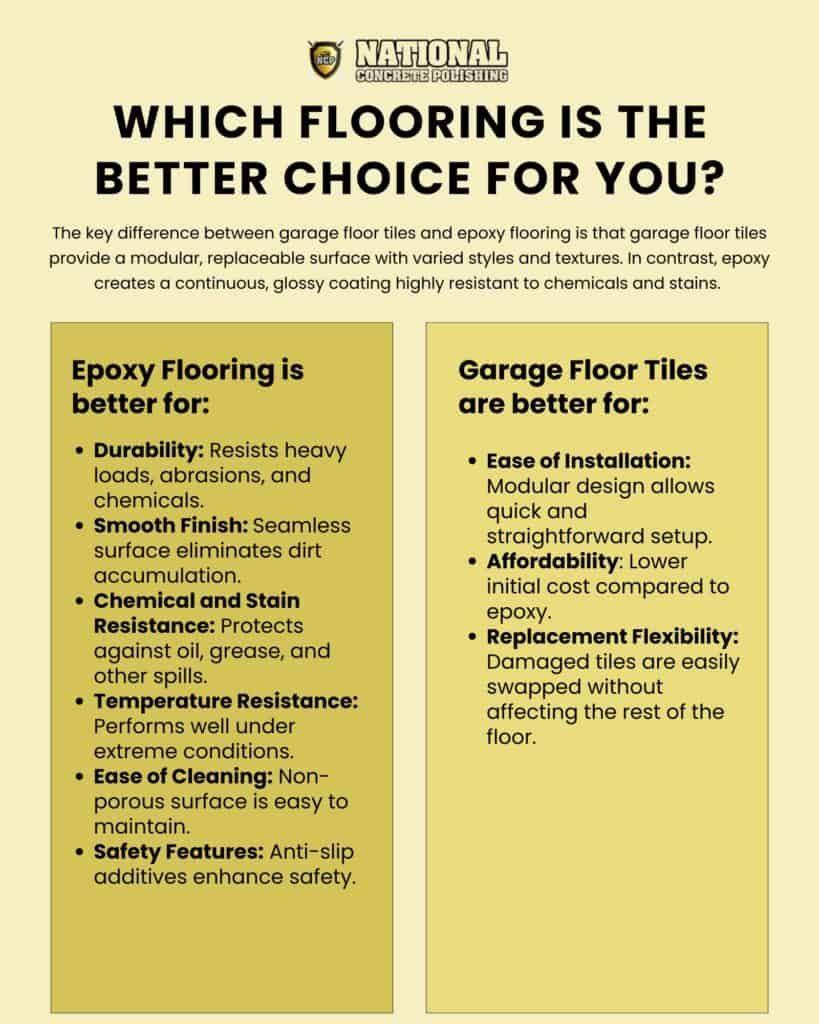

The key difference between garage floor tiles and epoxy flooring is that garage floor tiles provide a modular, replaceable surface with varied styles and textures. In contrast, epoxy creates a continuous, glossy coating highly resistant to chemicals and stains.

The factors that impact the lifespan of both garage floor tiles and epoxy flooring include the quality of the materials, installation techniques, maintenance practices, and exposure to heavy impacts and chemical spills.

The maintenance requirements for garage floor tiles involve routine cleaning and occasionally replacing damaged tiles, making them easy to maintain. Epoxy flooring requires minimal maintenance but benefits from periodic cleaning and occasional recoating to preserve its glossy appearance and protective qualities.

What Are Garage Floor Tiles?

Garage floor tiles are modular flooring systems made from materials such as PVC, rubber, or polypropylene. These tiles are designed to protect garage floors from damage while enhancing their appearance. The two main types are interlocking tiles, which snap together for easy installation, and peel-and-stick tiles, which adhere directly to the surface for a seamless finish.

Garage floor tiles are known for their durability, ability to endure heavy loads, and frequent use. They also offer aesthetic versatility, with a variety of colors, textures, and patterns to suit any style. Their ease of installation and maintenance makes them a practical and customizable flooring solution for garages.

What Is Epoxy Flooring?

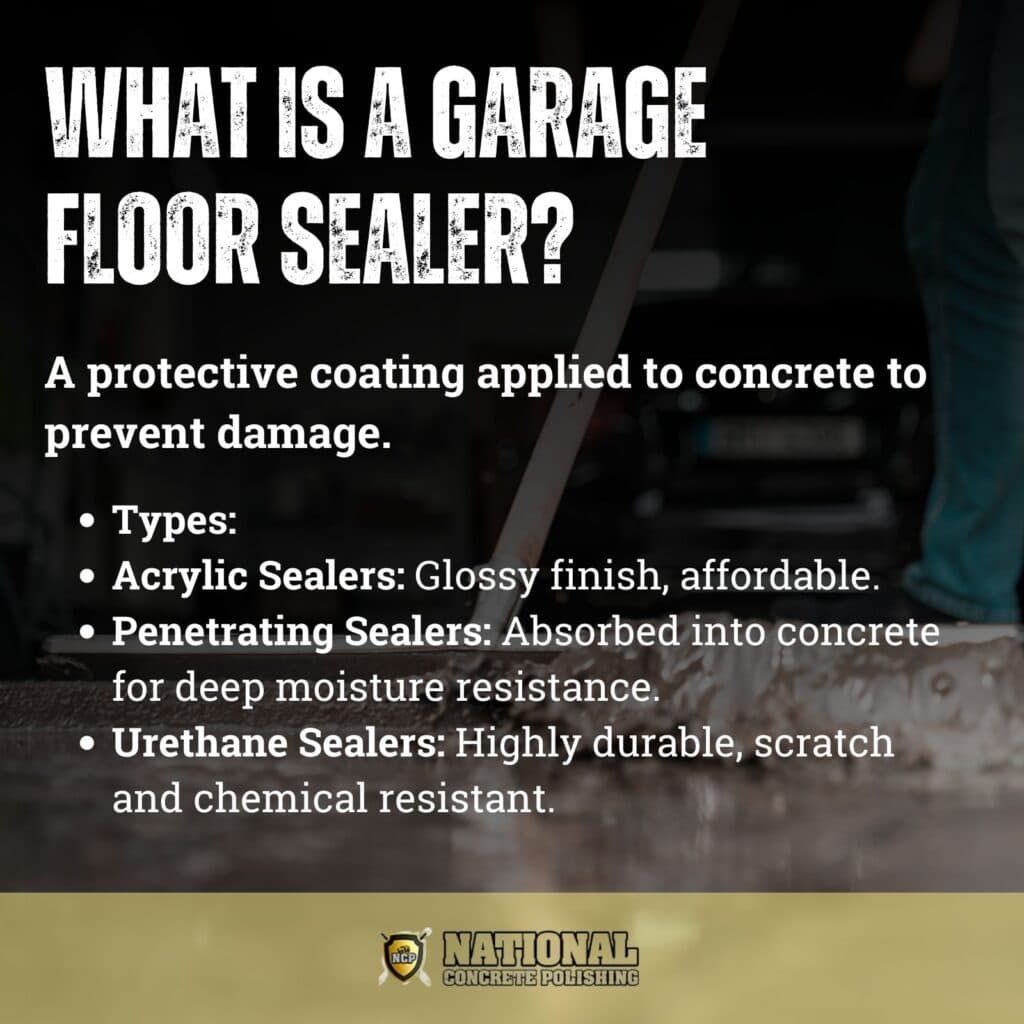

Epoxy flooring is a durable surface created by applying a mixture of resin and hardener onto concrete. This chemical composition forms a strong bond with the concrete, creating a seamless and long-lasting finish. The application process involves preparing the concrete surface, applying the epoxy mixture, and allowing it to cure, resulting in a hard, glossy layer.

Epoxy flooring is highly resistant to stains, chemicals, and abrasions, making it a popular choice for high-traffic areas like garages, warehouses, and commercial spaces. Its durability and sleek, customizable finish add both functionality and aesthetic appeal, making it an excellent flooring solution for demanding environments.

How Do Garage Floor Tiles and Epoxy Compare in Durability?

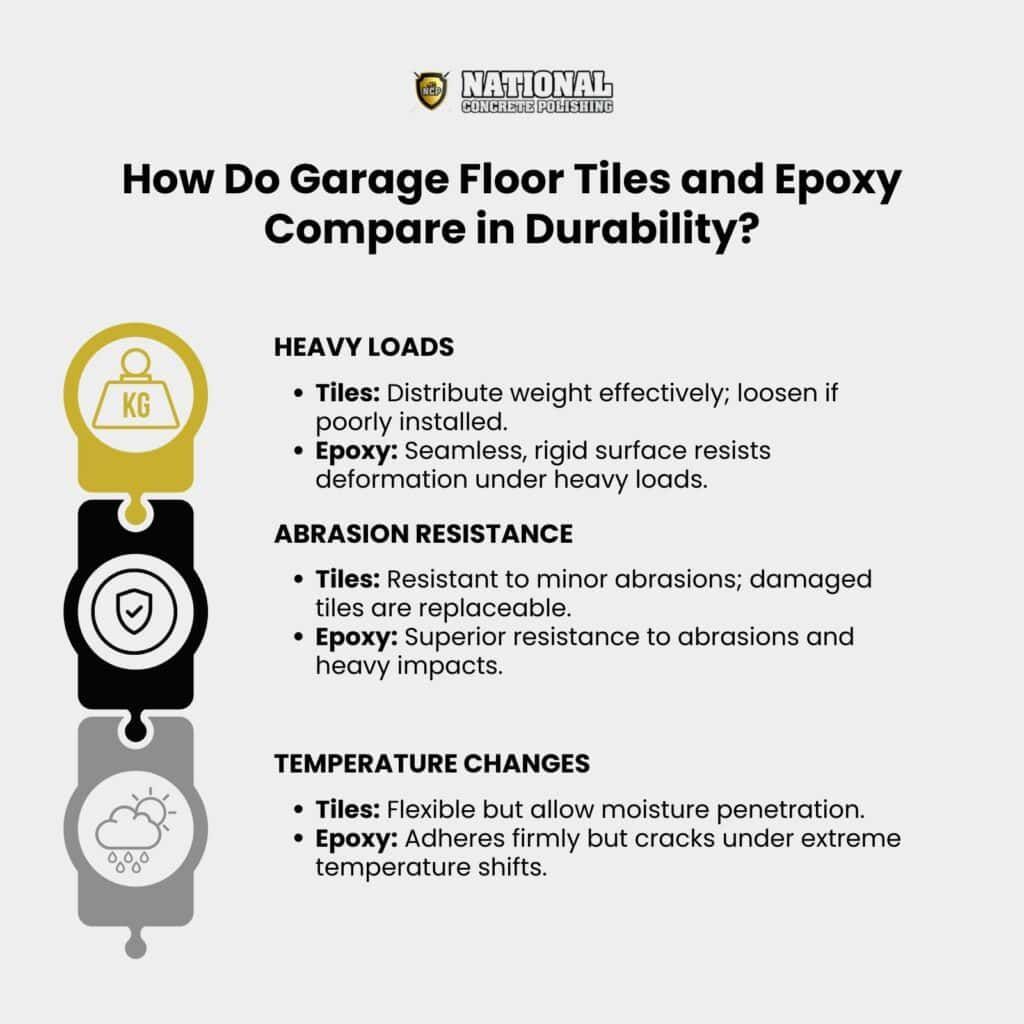

The ways by which garage floor tiles and epoxy compare in durability are heavy loads, abrasions, and environmental conditions. Each option offers unique characteristics that impact its performance and longevity.

The ways by which garage floor tiles and epoxy compare in durability include:

- Heavy Loads: Garage floor tiles are designed to withstand heavy weight due to their modular structure, which effectively distributes pressure. However, if not installed properly, they shift or loosen under prolonged heavy use.

Epoxy flooring, with its seamless, rigid surface, provides excellent strength and resists deformation under heavy loads, making it highly durable for demanding applications.

- Abrasion Resistance: Garage floor tiles are resistant to surface-level abrasions and impacts, and individual tiles are replaced if damaged.

Epoxy flooring offers superior resistance to abrasions. Its hard, protective surface shields against wear from tools, vehicles, and other heavy objects.

- Temperature Changes: Garage floor tiles handle temperature changes well due to their flexible nature, although gaps between tiles allow moisture to penetrate.

Epoxy flooring adheres firmly to concrete and resists most environmental effects, but extreme temperature fluctuations, especially when the substrate shifts, cause cracks.

Which Option Is Easier to Install?

The easiest option to install is garage floor tiles. Due to their modular design, garage floor tiles are simpler to install. Interlocking tiles snap together effortlessly, requiring minimal preparation and no adhesives. Peel-and-stick tiles are also simple, adhering directly to a clean surface with basic tools like a utility knife and measuring tape.

Epoxy flooring, however, requires a more thorough and time-consuming process. Preparing the surface involves cleaning, repairing, and etching the concrete to ensure proper adhesion.

The epoxy mixture must be applied in layers using rollers or squeegees and requires several days to cure fully. Specialized tools such as a concrete grinder or acid etcher, along with protective equipment, add complexity to the process.

Garage floor tiles offer convenience and ease of installation, making them the preferred choice for those looking for a quick and manageable solution. Epoxy, while more complex, delivers a seamless and durable finish for those willing to invest the time and effort.

Which Flooring Type Offers Better Aesthetic Options?

The flooring type that offers better aesthetic options is epoxy flooring. This is because epoxy flooring offers a smooth, high-gloss finish with customizable color options, metallic effects, and decorative flakes, which create a sleek and modern look.

Epoxy includes vibrant hues, gradients, and beautiful patterns, giving it an advantage for those seeking a polished, professional appearance. Its uniform surface enhances the visual appeal of any garage, making it an excellent choice for a cohesive, high-end aesthetic.

However, garage floor tiles are versatile but focus more on modular design and pattern flexibility. They come in different textures and finishes that allow homeowners to create unique layouts like checkerboard or striped designs. Interlocking tiles are particularly effective for combining colors to suit individual tastes, but their segmented appearance lacks the sleekness of epoxy.

How Do Maintenance Requirements Differ for Each Option?

The maintenance requirements for garage floor tiles include regular cleaning to remove dirt and debris and occasional replacement of damaged tiles. Their modular design makes repairs easy since individual tiles can be swapped without affecting the rest of the floor. Garage floor tiles are resistant to most stains, but spills that seep through the seams require additional cleaning of the underlying surface. Proper upkeep ensures they retain their appearance and functionality over time.

Epoxy flooring, in contrast, demands minimal maintenance but benefits from periodic cleaning to remove dust, dirt, and spills. Its smooth surface resists stains and is easy to wipe clean, making it highly effective against oil, grease, and chemical spills common in garages. However, repairing epoxy is more challenging. Professional assistance is required to reapply or patch damaged areas, especially when cracks develop over time.

Which Option Is More Cost-Effective in the Long Run?

Epoxy flooring is the more cost-effective option in the long run. However, epoxy flooring has higher upfront costs, including the price of materials and professional installation. The process involves surface preparation, application, and curing, which contribute to the overall expense.

Despite this, epoxy flooring’s seamless, durable surface requires minimal maintenance and is highly resistant to wear, stains, and damage, reducing long-term repair costs. With proper care, epoxy flooring lasts longer than tiles, making it a cost-effective investment over time.

Garage floor tiles generally have lower initial costs, with prices varying based on the material, style, and brand. Interlocking tiles are relatively affordable and easy to install, saving on labor expenses. However, the long-term cost increases due to the need for periodic repairs or replacements, especially in high-traffic areas where tiles loosen or wear over time.

Which Flooring is the Better Choice for You?

Epoxy garage flooring is the better choice for you because of its durability, smooth finish, customization options, chemical and stain resistance, temperature resistance, ease of cleaning, longevity, and safety features. While garage floor tiles are a practical option for quick and budget-friendly installation, epoxy offers more solutions for heavy-duty use.

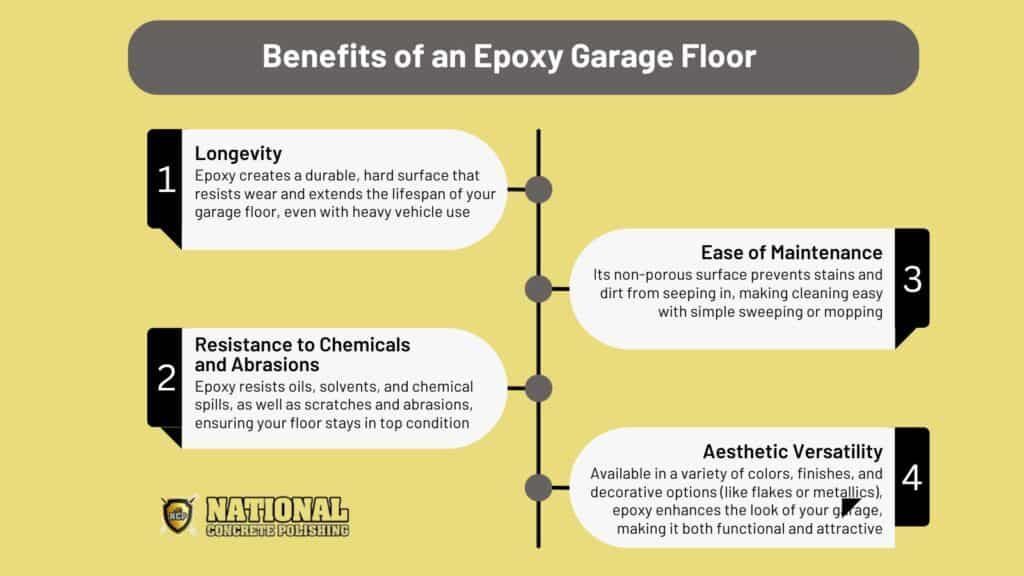

The reasons why epoxy flooring is a better choice include:

- Durability: This is the surface’s ability to withstand physical stress. Epoxy flooring resists heavy loads, abrasions, and chemicals, making it a reliable option for garages with frequent vehicle traffic or industrial-grade equipment. Its chemical bond with the concrete base ensures a resilient and long-lasting surface.

- Smooth Finish: Epoxy flooring’s continuous, joint-free surface not only looks sleek but also eliminates gaps where dirt, moisture, and debris accumulate, simplifying maintenance and cleaning.

- Customization Options: This is the ability to alter the floor’s design. Epoxy offers advanced aesthetic options, including high-gloss finishes, metallic designs, color blends, and decorative flakes, giving homeowners the ability to create a unique and professional-looking garage floor.

- Chemical and Stain Resistance: This is the surface’s ability to resist damage from oils and other substances. Epoxy flooring is impervious to oil, grease, gasoline, and other harsh chemicals commonly found in garages. This resistance protects the surface and maintains its appearance over time.

- Temperature Resistance: This is the ability of a material to remain stable under heat or cold. Epoxy performs well under extreme temperature changes, resisting cracking and surface degradation, which makes it an excellent choice for garages in varying climates.

- Ease of Cleaning and Maintenance: This is the minimal effort required to keep the surface clean. Epoxy’s non-porous surface repels spills, dirt, and grime, requiring only basic cleaning to keep it looking pristine. Its resistance to staining further reduces maintenance efforts.

- Longevity: This is the extended lifespan of a surface, with minimal repairs or replacements needed over time. With proper installation and minimal upkeep, epoxy flooring lasts for decades, providing an exceptional return on investment compared to other flooring options.

- Safety Features: These are the anti-slip properties that reduce the risk of falls and accidents. Epoxy coatings are customized with anti-slip additives, making the garage safer by reducing the risk of slips and falls, especially in wet conditions.

You might also like