Polyaspartic Floor Coating vs Epoxy: A Complete Comparison

Polyaspartic and epoxy are two popular choices for both residential and commercial applications. Polyaspartic coatings are a type of polyurea that offers fast curing times, excellent UV resistance, and extreme durability, making them ideal for high-traffic areas or outdoor spaces. Epoxy coatings, on the other hand, are known for their cost-effectiveness, chemical resistance, and glossy finish, used in industrial and indoor settings where durability and aesthetics are key concerns.

The differences of polyaspartic floor coatings and epoxy floor coatings are significant in application conditions, cure time, and cost. Polyaspartic coatings cure much faster, usually within hours, and can be applied in a wider range of temperatures, making them versatile for various environments. Epoxy coatings, however, take several days to cure and are best applied in controlled temperature settings. Polyaspartic also tends to be more durable and scratch-resistant, while epoxy is more prone to wear over time, especially in areas exposed to UV light.

The ideal surfaces for each type of coating also vary. Polyaspartic coatings are perfect for garages, outdoor patios, and high-traffic commercial spaces, thanks to their UV resistance and fast return to service. Epoxy coatings excel in basements, warehouses, and indoor industrial floors, offering strong chemical resistance and an easy-to-clean surface.

To choose between the two , it’s importantl to consider factors such as environmental conditions, budget, desired finish, and maintenance needs. If you need quick installation and superior durability for outdoor or high-traffic spaces, polyaspartic may be the better choice. However, for cost-effective, indoor applications, epoxy could be the most suitable option.

What is Polyaspartic Floor Coating?

Polyaspartic floor coating is a high-performance floor finish renowned for its rapid curing time, durability, and resistance to stains, abrasions, and chemicals. Originating from polyurea technology, this coating is an advancement that provides a versatile solution for both commercial and residential flooring needs. Unlike traditional coatings such as epoxy, polyaspartic coatings are applied in a wide range of temperatures, making them ideal for various climates and year-round installations.

Its quick curing process allows for faster project completion, significantly reducing downtime in commercial settings and inconvenience in homes. Additionally, polyaspartic floor coatings offer UV stability, which prevents yellowing over time, ensuring the floor maintains its aesthetic appeal longer. With its ability to be customized through colors and decorative chips, polyaspartic coatings not only protect floors but also enhance their appearance, making it a popular choice for garages, warehouses, retail spaces, and other high-traffic areas.

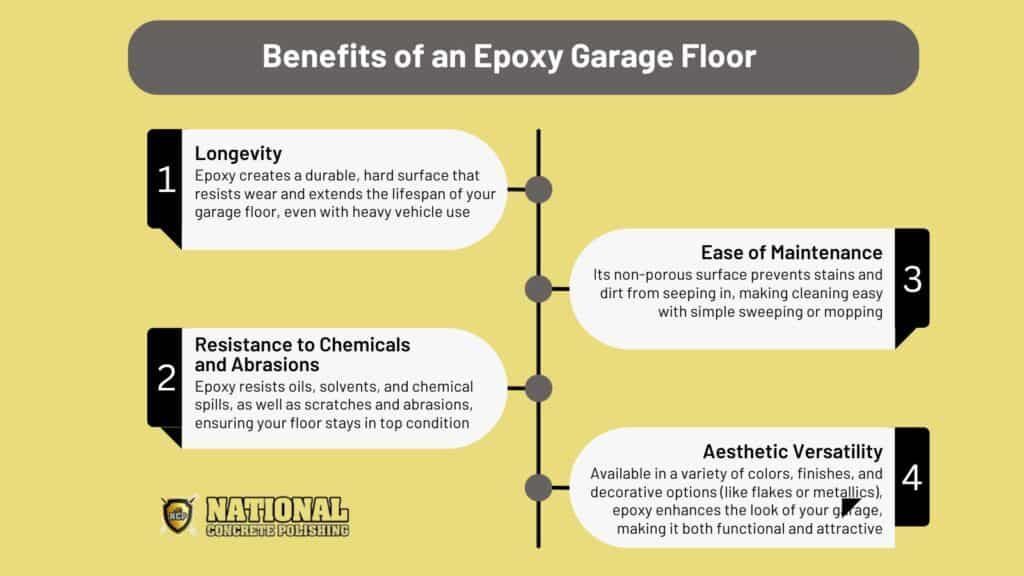

What is Epoxy Floor Coating?

Epoxy Floor Coating is a durable and protective surface layer that combines resin and hardener, resulting in a hard, plastic-like surface. This type of coating is known for its strength, durability, and resistance to wear, making it suitable for floors that endure heavy traffic and harsh conditions. Epoxy coatings are used in industrial and commercial settings, such as warehouses, factories, and garages, due to their ability to withstand chemicals, stains, and impacts.

The application process of epoxy floor coatings allows for a seamless and smooth finish that incorporates various colors and decorative patterns, offering both functionality and aesthetics. Despite its toughness, epoxy is prone to scratches and yellows over time when exposed to UV light. Its application requires specific temperature conditions and a longer curing time compared to polyaspartic coatings, which limits its use in certain environments and extends project timelines.

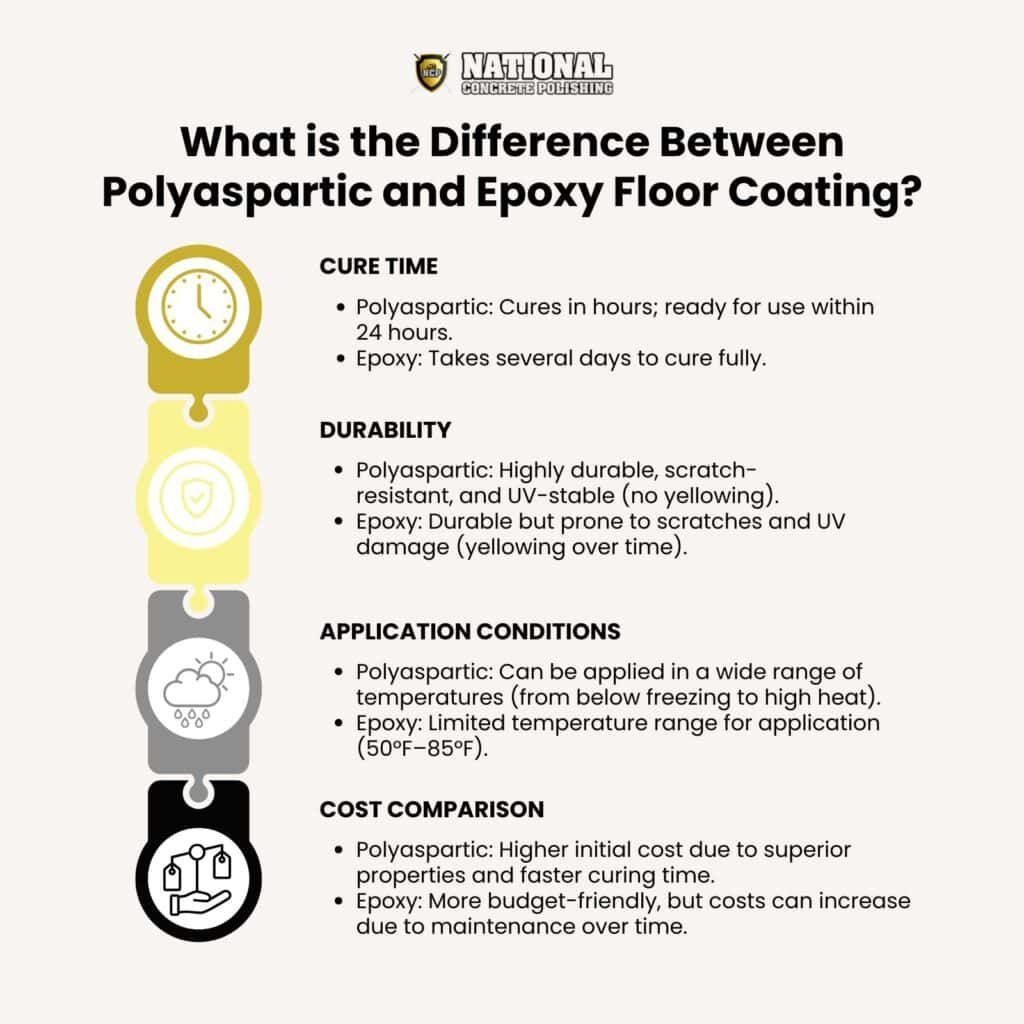

What is the Difference Between Polyaspartic and Epoxy Floor Coating?

The main differences between polyaspartic floor coating and epoxy floor coating is their curing time, application conditions, durability, and cost. Polyaspartic coatings offer a quick return to service, which is ideal for environments that cannot afford long downtimes. In contrast, epoxy coatings require days to fully cure, potentially extending project timelines.

The differences between polyaspartic coatings and expoxy floor coatings include:

Cure Time

- Polyaspartic : Polyaspartic coatings cure extremely fast, typically within hours . Floors are ready for use in 24 hours or less, making them ideal for quick-turnaround projects.

- Epoxy : Epoxy coatings take significantly longer to cure, requiring several days before the surface is ready for use. This extended curing time makes epoxy less convenient for fast-paced projects.

Durability

- Polyaspartic : Known for its high traffic resistance , polyaspartic coatings are highly durable, resistant to abrasions, UV damage, and chemical spills. This makes them well-suited for areas with heavy foot traffic or exposure to sunlight, like garages or outdoor spaces.

- Epoxy : While durable, epoxy is more prone to scratches and abrasions over time, especially in high-traffic areas. It also tends to yellow or fade when exposed to UV light, limiting its application for outdoor use.

Application Conditions

- Polyaspartic : Applied in a wide range of temperatures , from below freezing to high heat. This flexibility allows it to be used year-round and in varying environments without issues.

- Epoxy : Has a limited temperature range for application, generally between 50°F to 85°F. Outside of this range, the epoxy does not cure properly, which restricts its usability in extreme climates or seasons.

Cost

- Polyaspartic : Generally has a higher initial cost , ranging from $6 to $12 per square foot , due to its superior properties and quicker cure time. However, its long-term durability and resistance offsets these upfront expenses by reducing future maintenance costs.

- Epoxy : More cost-effective upfront , with installation costs typically ranging from $3 to $7 per square foot . While cheaper initially, epoxy requires more maintenance or refinishing over time due to its susceptibility to scratches and UV damage.

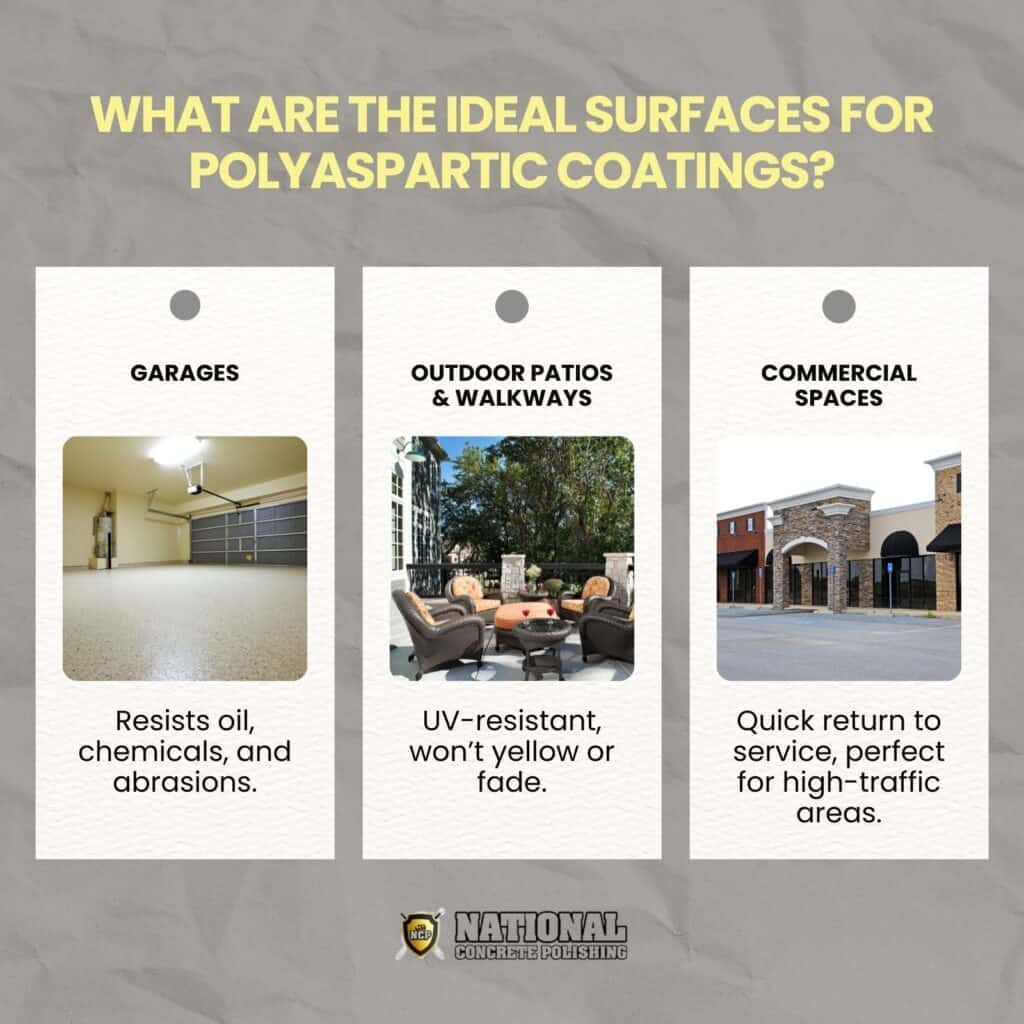

What are the Ideal Surfaces for Polyaspartic Coatings?

The ideal surfaces for polyaspartic coatings are those that benefit from its quick cure time, durability, and UV resistance. Commercial spaces choose polyaspartic coatings for their ability to handle high foot traffic and return to service rapidly, minimizing downtime. Garages also favor this option due to its resistance to oil, chemicals, and abrasions, ensuring a long-lasting and resilient surface.

Additionally, areas with high UV exposure greatly benefit from polyaspartic coatings, as they maintain their color and finish without yellowing over time. This makes it an excellent choice for outdoor spaces or any areas subject to direct sunlight.

The ideal surfaces for polyaspartic coatings are written below:

- Garages : Polyaspartic coatings are perfect for garage floors because they resist oil, chemicals, and abrasions. They provide a long-lasting, resilient surface that withstands vehicle traffic and chemical spills without deteriorating.

- Commercial Spaces : Retail stores, shopping centers, and warehouses benefit from polyaspartic coatings due to their ability to handle high foot traffic and quick return to service. This minimizes downtime, which is crucial for business operations.

- Outdoor Spaces : Patios, walkways, and outdoor recreational areas are ideal for polyaspartic coatings because they offer excellent UV resistance. This prevents yellowing and fading over time, maintaining a fresh, clean appearance.

- Industrial Facilities : Factories and workshops that experience heavy machinery and equipment use are also ideal candidates for polyaspartic coatings due to their superior durability and resistance to abrasions.

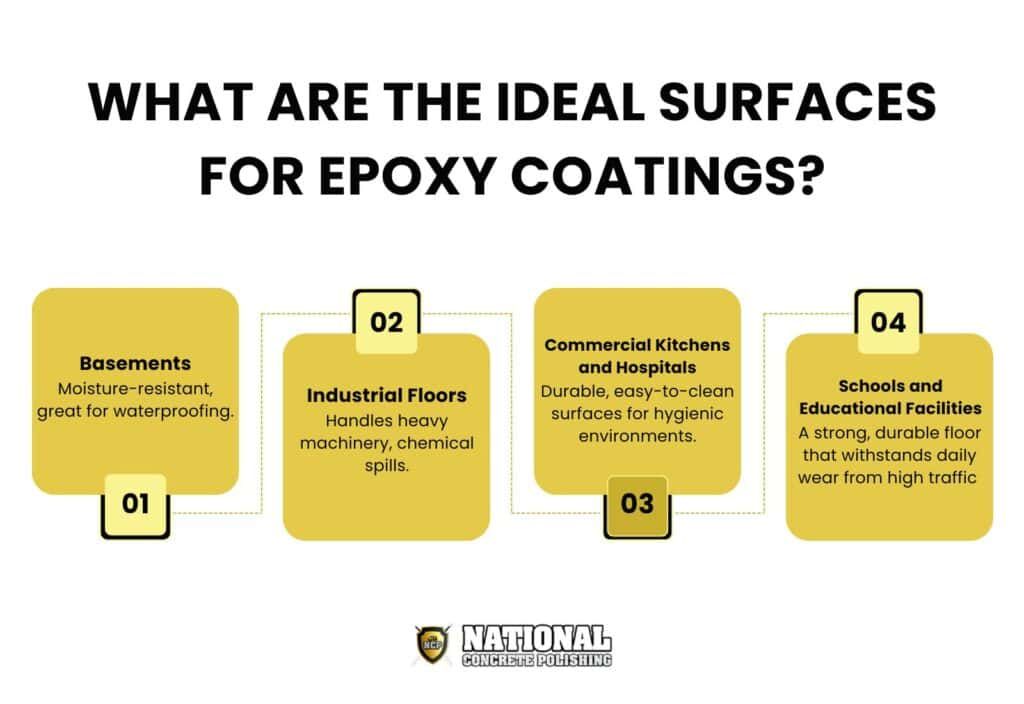

What are the Ideal Surfaces for Epoxy Coatings?

The ideal surfaces for epoxy coatings are those that require a robust, protective layer capable of withstanding harsh conditions. Industrial floors benefit greatly from epoxy’s durability and resistance to chemicals , making it a preferred choice for factories and warehouses where spills and heavy machinery are common. Basements are also well-suited for epoxy coatings due to their resistance to moisture , providing a waterproof barrier that helps protect the underlying concrete from water damage.

Additionally, high-traffic areas such as commercial kitchens, hospitals, and schools take advantage of epoxy’s ability to withstand constant foot traffic while maintaining a clean, glossy appearance. This makes epoxy coatings a versatile and practical solution for a wide range of environments that demand strength and longevity.

The ideal surfaces for epoxy coatings are written below:

- Industrial Floors : Factories and warehouses benefit from epoxy’s ability to withstand heavy machinery, chemical spills, and high wear and tear. Its durability makes it a go-to choice for environments with significant physical impact.

- Basements : Epoxy is excellent for basement floors as it provides a moisture-resistant barrier. This waterproofing feature helps protect the concrete underneath from water damage, making it a practical choice for areas prone to moisture.

- Commercial Kitchens and Hospitals : High-traffic areas like commercial kitchens , hospitals, and clinics benefit from epoxy’s clean, glossy appearance and resistance to foot traffic. Its ability to maintain a hygienic surface with minimal upkeep makes it ideal for health-sensitive environments.

- Schools and Educational Facilities : Epoxy is used in schools and public buildings, as it provides a strong, durable floor that withstands daily wear from high traffic and keeps a polished look for years.

How to Choose Between Polyaspartic and Epoxy Coatings?

To choose between polyaspartic and epoxy floors, start by assessing the environment in which the flooring will be applied, your budget, the aesthetics and finish you are looking for as well as the durability and maintenanceof the coating.

Factors to Consider When Choosing Between Polyaspartic and Epoxy Floors:

- Environment

:

- Polyaspartic : Ideal for areas with fluctuating temperatures and high UV exposure, such as garages, outdoor patios, and industrial settings.

- Epoxy : Best suited for controlled environments with stable temperatures, like basements, warehouses, or indoor facilities.

- Budget

:

- Polyaspartic : Higher initial cost (typically $6 to $12 per square foot ), but its faster cure time and durability can result in lower long-term maintenance expenses.

- Epoxy : More cost-effective upfront (usually $3 to $7 per square foot ), but requires more maintenance or refinishing over time, leading to higher future costs.

- Aesthetics and Finish

:

- Polyaspartic : Offers a variety of finishes, including glossy, matte, or decorative options, while providing superior UV resistance, preventing yellowing or fading in sunlight.

- Epoxy : Known for its smooth, glossy finish, but limited in UV protection, making it prone to yellowing in sunlit areas.

- Durability and Maintenance

:

- Polyaspartic : Highly resistant to scratches, abrasions, and chemicals, making it suitable for high-traffic areas and environments exposed to harsh chemicals.

- Epoxy : Durable and easy to clean, but more prone to scratching and chemical wear over time, which could increase maintenance needs in high-traffic or industrial settings.

By considering these factors, you can make an informed decision based on the specific environment, budget, aesthetic preferences, and long-term maintenance expectations for your flooring project.

You might also like